Companies in the food industry must also comply with all the regulations of the countries in which they are implemented. For example, if the company is based in Spain, it must comply with Law 17/2011 of July 5, 2011, on food safety and nutrition (see Spanish legislation on food safety by type of food) in addition to the European Regulation EC No. 178/2002 which is a regulation applied in all the European countries.

We interviewed Nan Ra, a specialist in Food safety issues, to help you make the right choice & offer the keys to understanding the differences and similarities between the food safety standards as well as the latest news.

What is IFS Food?

Established in 2003, IFS Food is an international certification that assesses the compliance of products and processes with food safety and quality. The IFS Food standard applies to suppliers at all stages of food processing after the raw material stage.

IFS also distinguishes its certification for the Logistics sector (IFS Logistics) and for trading, importing, brokering and trading activities.

What’s new in the latest version of IFS Food v8?

The latest version of IFS v.8 is in preparation and at the public consultation stage. The new features announced are:

- the integration of the Codex Alimentarius and the new ISO 22000-2 standard,

- the revision of the rating system (in particular the B rating),

- the clarification of the rule of the improvised (for example in case of audit failure),

- the possibility of reassigning certain criteria to follow the audit trail more accurately

- the reporting of mandatory fields

- consistency and accuracy of the wording and checklist

- adaptation of the certification process regarding the action plan and a preliminary rating instead of the preliminary report

What is BRC Food?

In the United Kingdom, 50% of food products are private labels, so it was necessary to develop a standardized, rationalized and optimized evaluation system for the suppliers of foodstuffs to the English supermarket sector.

Therefore in 1996, the British Retail Consortium (a British organization regrouping food retailers) developed the “Technical Reference for Private Label Suppliers” which is also known as the BRC standard.

The BRC defines a common base of food safety requirements for manufacturers of private label products in the UK market and standardizes audits.

BRC certification is obtained after an audit by an EN 45011-accredited certification body.

The company can be certified at the basic level or at a higher level.

What is new in the latest BRC v9 version?

The new requirements are related to:

- The validation of HACCP plans,

- The management of suppliers,

- Equipment monitoring (including X-ray foreign body detectors),

- Animal feed and primary processing,

- The reinforcement of the requirements for a “food safety culture”.

In addition to the realization of an unannounced audit every three years with the possibility to do part of the audit remotely.

Finally, the IFS Food and BRC Food standards differ from ISO 22000 not only by performance requirements but also because they set out obligations in terms of means.

What do the IFS and BRC standards have in common?

The BRC and IFS standards are internationally recognized quality and food safety certifications. They deal with the safety and quality of foodstuffs and seek continuous improvement of their processes. However, there are some differences to consider when deciding which certification is most appropriate for each industry.

How to prepare for the food safety certification assessment audit?

If you wish to have one of the food safety certifications, you must contact a certified and capable food safety auditor.

To prepare for your certification audit, it is a good idea to conduct a “dry run” of your food safety system beforehand. This will greatly help you to identify the improvement areas related to the sought certification and to comply with its requirements.

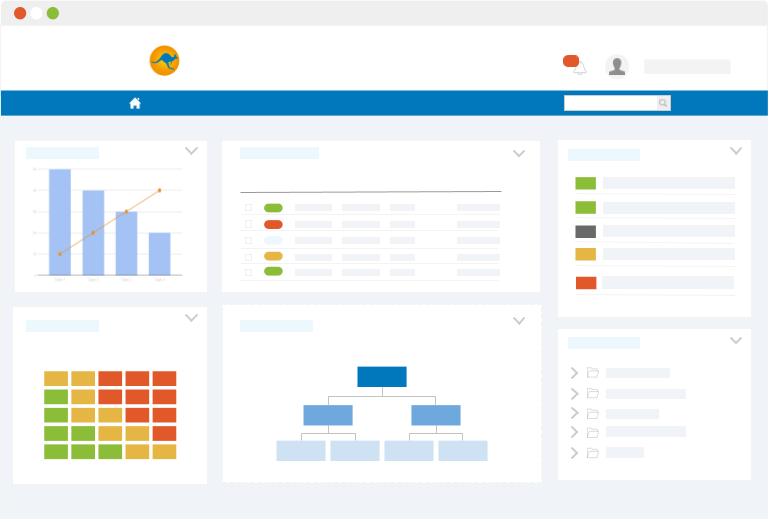

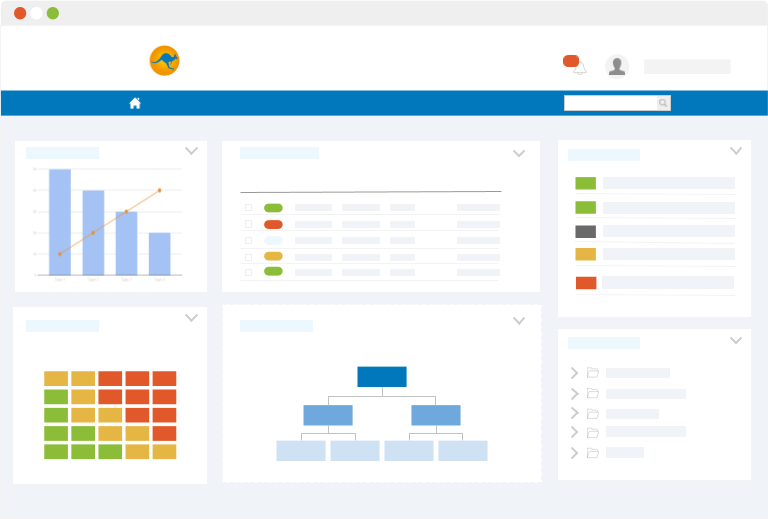

A solution like BlueKanGo can help you in this process.

BlueKanGo includes in its solution all the food safety standards such as IFS, BRC, and ISO 22000.

You can conduct your self-assessment directly in the application and generate live corrective actions associated with the requirements of the standard.

Based on this application, you can also position all the evidence of your system in front of each requirement of the standard to facilitate your audit, especially if it takes place unexpectedly.

Furthermore, a solution like BlueKanGo allows you to collect data at the source in a structured way by reproducing your own registration forms and automatically generating associated tasks for the people concerned.

You can thus digitize your food safety processes to gain productivity but also boost the involvement of your teams in your continuous improvement process.

In order to ensure that you do not have any non-conformities, you need to prepare and organize yourself in a way that fully meets the requirements of the standard. Digitalization is a major asset to guarantee that you fully meet the requirements and can save you time (data collection, global action plan, alerts in case of deviation).

How to switch from IFS Food to BRC 9 certification (and vice versa)

You are already certified to one food safety standard and want to validate another. If they have certain similarities, online tools can allow you to capitalize on the validation of requirements found similar in both of them.

BlueKanGo software integrates the major food safety standards. You can compare the requirements of one with those of the other. You can specify the actions taken to meet the requirements.

For example, you have all the evidence for the IFS Food standard. On the other side, you have the requirements of the BRCGS v9 standard. You can quickly identify which elements need to be completed in order to comply with the BRCGS v9 standard.

This self-assessment tool prepares you efficiently for the evaluation of the BRCGS v9 standard. You have all the elements at hand during the auditor’s visit.

Conclusion

Food safety is essential, and too many cases of fraud and security breaches underline the essential nature of integrating a prevention and monitoring strategy at every stage of processing and distribution. Regulations are constantly evolving and are significantly different depending on the markets in which you work. Certifications are important for many consumers and other stakeholders (suppliers, distributors, food processors…).

A digital tool will help you organize your actions and engage your employees in a continuous improvement and controlled food safety approach.