What is the definition of non-conformities?

A non-conformity is a malfunction or deviation that occurs during an activity or a process.

What are the types of non-conformities?

There are 2 types of NC :

- Minor” NC: this is an easily identifiable malfunction that does not have significant consequences. This type of NC can be quickly resolved.

For example the absence of an updated version of a certain document, the bad calibration of a machine, etc.

- Major” NC (also called “critical”): This is a malfunction that is difficult to identify and that can have a major impact on the quality of the product or process concerned.

For example the shipment of uncontrolled products, an allergenic labeling defect on a product, etc.

However, a malfunction can be identified as a “minor NC”, and can be afterward requalified as a “major NC”, depending on the consequences of the NC.

How to detect non-conformities (the steps)?

Several steps are necessary to manage non-conformities:

1 – Detecting and recording the non-conformity

Once identified, the NC must be recorded quickly to limit the impact.

All employees are encouraged to participate in this continuous improvement process.

2 – Quickly implement corrective actions

This involves eliminating or mitigating the risk at the source to prevent the situation from getting worse.

3 – Analyze the possible causes

A dedicated working group is set up, with the actors concerned by the NC, to carry out an analysis of the possible causes.

For this analysis, you can rely on methods such as the 5M diagrams, the 5 W’s (Who, What, Where, When, Why ?), or the root cause tree.

4 – Implementing corrective actions

In order to prevent the NC from happening again, you will set up several actions, which you will assign to your different managers. It is important to ensure that each manager has the necessary means and resources to take corrective actions.

5 – Follow up actions and continuous improvement

To ensure the continuous improvement of the system, and the follow-up of the actions previously established, it is possible to

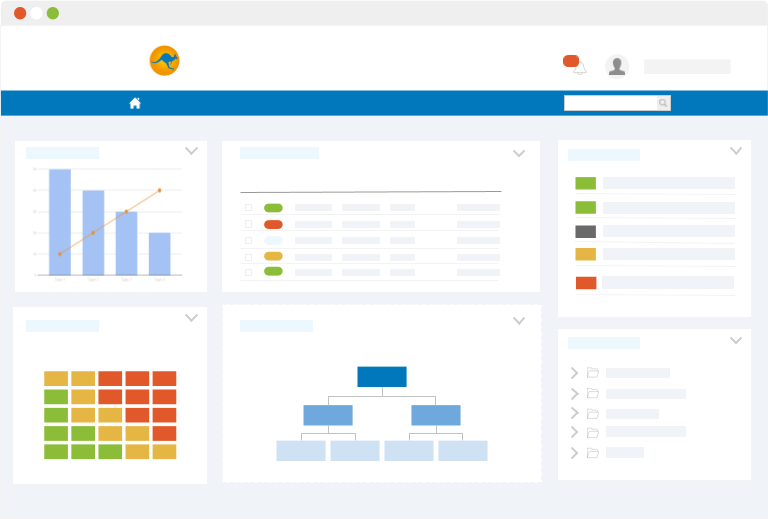

Different tools such as the internal audit and the establishment of dashboards could help you to ensure the continuous improvement of the system, and the follow-up of the actions previously established. You can measure the global performance of the system thanks to specific indicators (KPI/KRI).

How can you effectively manage these non-conformities?

To efficiently manage your non-conformities, you can rely on a dedicated solution. These applications are adapted to the reality of the field: real-time data collection and sharing, implementation, and follow-up of corrective actions… You limit the risk of error by using a file in the wrong format (or the wrong version). You can also edit reports and NC declaration forms in PDF format (or in Excel). The objective is to save time in entering information, thanks to the centralization and automated processing of data.

Conclusion of the expert

The management of NC is a complex mission, which requires time in the daily life of Quality Managers. The collection and processing of information can be done by a digital tool: the NC sheets are filled out directly in the field, via a smartphone or a tablet, and real-time alerts and notifications for the quality department.

A global action plan centralizes all the actions launched from the NC sheets. In an operational way, it is possible to automatically assign corrective actions to each pilot.